News

27.12.2018

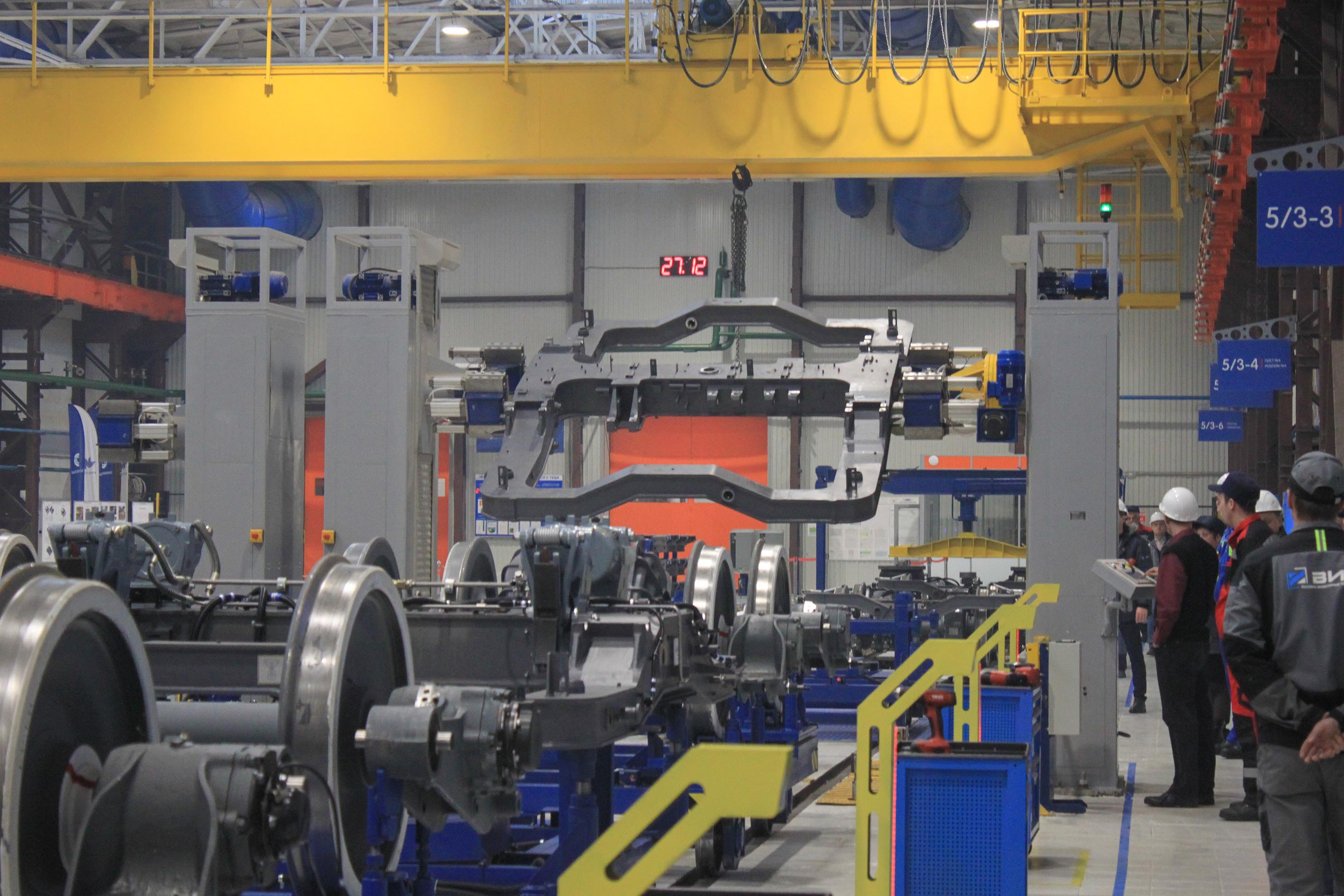

December 27, 2018 in the JSC "Metrowagonmash" in a solemn ceremony launched an automated assembly line for bogies of rolling stock.

The capacity of the new line is more than 1,500 bogies per year, which is almost 40% more than the capacity of bogie production currently existing at the enterprise. The technical characteristics of the assembly line are adapted to the tools of Industry 4.0 (access to reference documentation at the workplace; rationing and control of the category of losses, etc.).

Flow automated bogie assembly line was developed and implemented by MWM specialists within 9 months. About 300 tooling items were manufactured for the new line. Instead of the existing traditional stack assembly, a flow bogie assembly line with automated control of programmable logic controllers is organized.

The line is divided into 6 assembly stations, which are organized by the integrated delivery of all components. Moving of bogie from one post to another occurs in automatic mode, is controlled by radio signals and controllers. The line is controlled by the central computer, and three interactive monitors display the movement of each post, the causes of downtime or equipment breakdown.

Putting the line into operation will significantly reduce the assembly time of bogies and increase productivity by 30%; at the same time, as before, high quality of products will be provided.

Transmashholding invested about 35 million rubles into new bogie production. The estimated payback period of the project is less than 2 years.

Andrei Balyukin, Chief Technologist of MWM:

“This line is made according to the most up-to-date technological characteristics, allowing to increase the existing capacities of the enterprise. The line was designed by Metrowagonmash engineers, specialists from all departments of the enterprises took part in the project. The line is built according to the automatic scheme of movement, is controlled by digital controllers, the logistics controller is innovative because it is made according to the most modern technologies. A large aspect is given to ergonomics, many operations were performed manually, by hard work, all of which gave temporary losses and logistical difficulties. Here, these tasks have been solved - the line allows to supply the entire complete set kits to each of the six posts, all the means of mechanization are applied (automated relocation bogies). ”